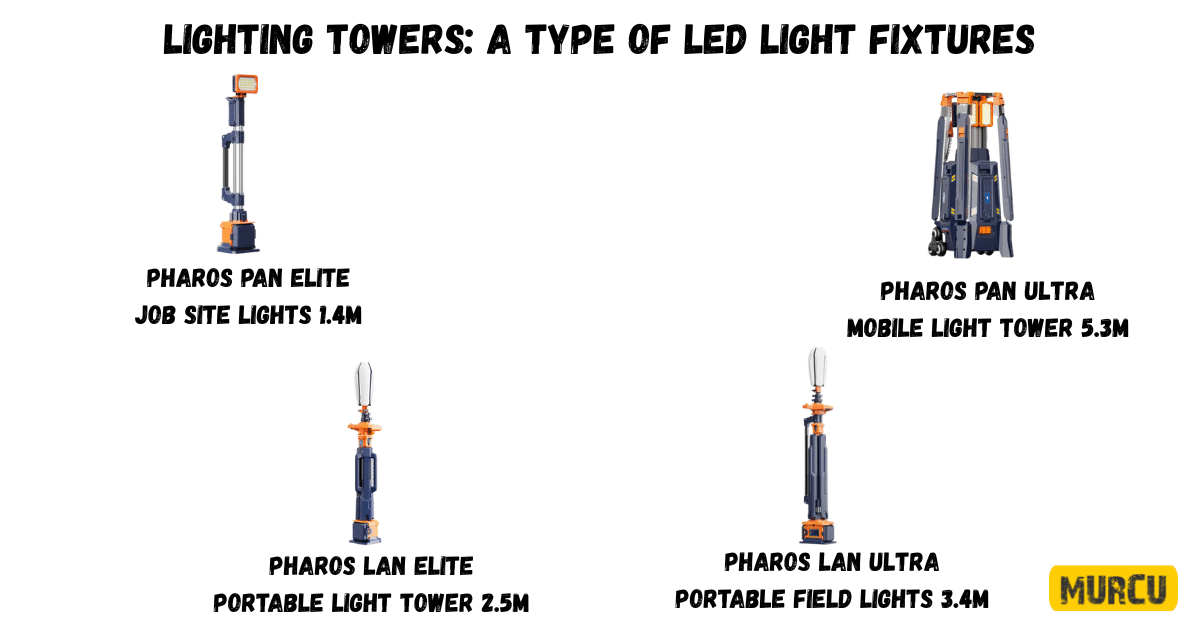

Lighting Towers: A Type of LED Light Fixtures

Lighting towers are tall, movable machines that provide bright light in places where regular lighting is not available. They are often used at night or in dark areas, such as construction sites, road works, emergency zones, or outdoor events. Their main job is to help people see better and stay safe while working or attending an event.

In this article, we will explain everything you need to know about lighting towers—their types, uses, benefits, how to choose one, and how to care for them—in simple and clear language.

What Is a Lighting Tower?

A lighting tower is a machine with one or more strong lights mounted on a tall pole (called a mast). This pole can go up and down, and the whole machine usually stands on wheels or a trailer to move easily.

The lights on the tower can be powered by different sources—a diesel generator, solar power, batteries, or a combination of these. Lighting towers are made to work in outdoor areas without street lighting or electricity.

Key Parts of a Lighting Tower

Lighting towers comprise several key components that provide effective and reliable illumination in various settings. Here are the primary parts of a typical lighting tower:

1. Trailer/Base

The trailer or base serves as the foundation of the lighting tower, providing mobility and stability. It typically includes wheels for transportation and stabilizing outriggers to secure the unit during operation.

2. Generator

An integrated generator supplies the necessary power to operate the lighting system. Most lighting towers utilize diesel-powered generators, though some models may use alternative power sources.

3. Mast

The mast is a vertical structure that elevates the lighting fixtures to a desired height, enhancing the coverage area. Masts can be telescopic and are often raised and lowered using manual or electric winches.

4. Lighting Fixtures

These primary illumination sources are mounted at the top of the mast. Modern lighting towers often feature high-intensity LED lamps, which offer energy efficiency and long service life.

5. Electrical System

The electrical system encompasses all wiring, control panels, switches, and safety mechanisms that distribute power from the generator to the lighting fixtures and other components.

Types of Lighting Towers

Lighting towers are essential for illuminating various settings, such as construction sites, outdoor events, emergencies, and more. They come in diverse types, each tailored to specific operational needs and environments. Below is an overview of the main types of lighting towers:

1. Diesel-Powered Light Towers

- Power Source: Diesel engine

- Advantages: Offers consistent and reliable performance; suitable for remote locations without access to electricity

- Considerations: Higher fuel consumption, ongoing maintenance requirements, and environmental impact due to emissions

- Common Uses: Construction sites, mining operations, and significant outdoor events

2. Battery-Powered Light Towers

- Power Source: Rechargeable batteries

- Advantages: Quiet operation, zero emissions, and reduced operating costs

- Considerations: Limited run time depending on battery capacity; may require frequent recharging for extended use

- Common Uses: Urban construction sites, indoor events, and areas with noise restrictions

3. Solar-Powered Light Towers

- Power Source: Solar panels with battery storage

- Advantages: Environmentally friendly, low operating costs, and minimal maintenance

- Considerations: Performance dependent on sunlight availability; may not be suitable for all climates

- Common Uses: Sustainable projects, remote locations, and eco-sensitive areas

4. Hybrid Light Towers

- Power Source: Combination of diesel engine and battery or solar power

- Advantages: Enhanced fuel efficiency, reduced emissions, and flexibility in power sources

- Considerations: Higher initial investment; complexity in maintenance due to multiple power systems

- Common Uses: Projects requiring extended operation with environmental considerations

5. LED Light Towers

- Lighting Technology: Light Emitting Diodes (LEDs)

- Advantages: Energy-efficient, long lifespan, instant illumination, and lower heat output

- Considerations: Higher upfront cost compared to traditional lighting

- Common Uses: General-purpose lighting across various industries due to durability and efficiency

6. Metal Halide Light Towers

- Lighting Technology: Metal halide lamps

- Advantages: High-intensity illumination suitable for large areas

- Considerations: Longer warm-up time, higher energy consumption, and shorter lifespan compared to LEDs

- Common Uses: Large-scale construction sites and events requiring intense lighting

7. Halogen Light Towers

- Lighting Technology: Halogen lamps

- Advantages: Lower initial cost and good color rendering

- Considerations: Shorter lifespan, higher heat output, and less energy-efficient

- Common Uses: Temporary lighting needs where cost is a primary concern

8. Inflatable Mast Light Towers

- Design Feature: Inflatable masts that elevate lighting fixtures

- Advantages: Lightweight, quick deployment, and compact storage

- Considerations: Less durable in extreme weather conditions; limited height compared to traditional masts

- Common Uses: Emergency response, military operations, and temporary events

9. Electric Light Towers

- Power Source: Direct connection to electrical grid or generator

- Advantages: Continuous operation without refueling; quiet and emission-free

- Considerations: Requires access to a power source; limited mobility

- Common Uses: Urban construction sites, indoor events, and areas with strict emission regulations

10. Hydrogen-Powered Light Towers

- Power Source: Hydrogen fuel cells

- Advantages: Zero emissions, quiet operation, and high efficiency

- Considerations: Emerging technology with limited availability; higher costs and infrastructure requirements

- Common Uses: Environmentally sensitive projects and areas with strict emission standards

Features of Lighting Towers

Lighting towers are essential for providing illumination in various settings, and their features have evolved to meet diverse operational needs. Here are some notable features of modern lighting towers:

1. Adjustable Mast Height and Rotation

Modern lighting towers often come with telescopic masts extending up to 30 feet, allowing for broad area coverage. Some models offer 360-degree mast rotation, enabling precise light direction without repositioning the entire unit.

2. High-Intensity LED Lighting

These towers, equipped with powerful LED fixtures, provide bright illumination while consuming less energy. For instance, specific models feature four 350-watt LED fixtures producing 228,560 lumens, ensuring adequate lighting for large areas.

3. Extended Fuel Efficiency

Lighting towers are designed for long-duration operations. Some can run up to 225 hours on a single fuel tank, reducing the need for frequent refueling and minimizing downtime.

4. Programmable Controls

Advanced models of light towers offer programmable features, such as automatic on/off settings based on ambient light conditions. This automation enhances efficiency and ensures consistent lighting without manual intervention.

5. Durable Construction

Many lighting towers are built to withstand harsh environments. They feature robust materials like heavy-duty steel enclosures and are wind-rated up to 65 mph, ensuring stability and longevity in challenging conditions.

6. Compact and Portable Design

Light towers are designed for easy transportation and storage, and some models have foldable components and compact footprints, allowing multiple units to be transported efficiently.

7. Auxiliary Power Outlets

Many lighting towers come equipped with auxiliary power outlets, providing additional power sources for tools and equipment, increasing their versatility on job sites.

8. Quiet Operation

Modern lighting towers are engineered to reduce noise levels, making them suitable for noise-sensitive environments like residential areas or nighttime operations.

Benefits of Lighting Towers

Lighting towers offer numerous benefits across various industries and applications. Here are some of the key advantages:

1. Enhanced Safety and Visibility

Lighting towers significantly improve visibility in low-light conditions, reducing the risk of accidents and injuries on sites like construction zones and roadworks. They enable workers to navigate obstacles, operate machinery safely, and precisely perform tasks.

2. Portability and Easy Setup

Light towers are designed for mobility; portable light towers can be quickly transported and set up in various locations. Their flexible design allows for rapid deployment with minimal adjustments, making them ideal for dynamic work environments.

3. Energy Efficiency and Cost Savings

Modern LED light towers are highly energy-efficient, consuming up to 80–90% less energy than traditional lighting solutions. This efficiency translates into significant cost savings on fuel and energy expenses.

4. Durability and Longevity

Light towers are constructed with robust materials like steel and are built to withstand harsh weather conditions and demanding work environments. Steel towers, in particular, offer high resilience, lower wear and tear, and a longer lifespan than alternatives made from plastic or fiberglass.

5. Environmental Benefits

LED lighting towers produce minimal emissions and operate quietly, making them environmentally friendly. Solar and hybrid models can reduce fuel consumption by up to 100%, contributing to a lower carbon footprint.

6. Versatility Across Applications

Lighting towers are versatile tools for various applications, including construction sites, mining operations, outdoor events, emergency response, and agricultural activities. Their adaptability makes them indispensable in multiple industries.

7. Reduced Maintenance Requirements

LED light towers have a longer operational life and require less frequent maintenance than traditional lighting systems. This reliability ensures consistent performance and reduces downtime.

Applications of Lighting Towers

Lighting towers are versatile and essential tools used across various industries to provide high-intensity illumination in areas lacking sufficient lighting. Their applications span from enhancing safety on construction sites to facilitating emergency response operations. Below is an overview of the primary applications of lighting towers:

1. Construction Sites

Lighting towers are indispensable on construction sites, especially for nighttime operations or during periods of limited daylight. They enhance visibility, allowing workers to perform tasks safely and efficiently, reducing the risk of accidents, and maintaining productivity.

2. Roadworks and Maintenance

During road construction or maintenance activities conducted at night, lighting towers provide the necessary illumination to ensure the safety of both workers and motorists. They help delineate work zones and guide traffic, minimizing the chances of accidents.

3. Outdoor Events

Light towers offer reliable lighting solutions for events such as concerts, festivals, and sports games held during evening hours. They illuminate large areas like parking lots, walkways, and event spaces, enhancing visibility and ensuring the safety and comfort of attendees.

4. Emergency and Disaster Relief

In the aftermath of natural disasters or during emergencies, lighting towers are crucial for rescue and recovery operations. They provide immediate and reliable lighting in areas where power infrastructure may be compromised, aiding emergency responders in their efforts.

5. Mining and Industrial Operations

In mining sites and industrial facilities, especially those operating around the clock, lighting towers ensure that work areas are well-lit. These not only facilitate continuous operations but also enhance the safety of workers by improving visibility in potentially hazardous environments.

6. Security and Surveillance

Lighting towers serve as a deterrent against theft and vandalism in construction sites, parking areas, and other vulnerable locations. By illuminating dark areas, they enhance the effectiveness of surveillance systems and contribute to overall site security.

7. Agricultural Activities

Farmers utilize lighting towers during nighttime agricultural activities, such as harvesting or planting, to extend working hours and improve efficiency. Adequate lighting ensures that tasks are performed accurately and safely, even after sunset.

8. Film and Television Production

In film and television production, especially for outdoor shoots conducted at night, lighting towers provide the necessary illumination to achieve desired lighting effects and ensure high-quality footage. They are essential tools for cinematographers and production crews.

9. Military and Defense Operations

Military operations often require portable and reliable lighting solutions for nighttime training exercises, base operations, and field missions. Lighting towers fulfill this need by offering flexible and robust illumination in various terrains and conditions.

10. Utility and Infrastructure Projects

Utility companies employ lighting towers to maintain and repair infrastructure such as power lines, pipelines, and communication networks. These towers enable technicians to work safely and effectively at night or in areas with limited natural light.

Installation of Lighting Tower

Installing a lighting tower involves several critical steps to ensure safety, stability, and optimal performance. The following guide outlines the standard procedure for setting up a lighting tower, incorporating best practices from industry sources.

1. Pre-Installation Safety Checks

- Inspect the Equipment: Before setup, thoroughly examine the lighting tower for any visible damage, such as cracks or rust. Ensure all components are in good condition.

- Check Fuel Levels: If the lighting tower operates on fuel, verify that the fuel tank is filled appropriately and inspect for leaks.

- Examine Electrical Components: Inspect all cables and electrical connections for wear or damage. Ensure that the wiring is intact and that there are no frayed or exposed cables.

- Ensure Proper Grounding: Confirm that the lighting tower is adequately grounded to prevent electrical hazards, especially in wet conditions.

2. Positioning the Lighting Tower

- Select a Stable Location: Choose a flat, level surface free from obstructions like trees or buildings that could block light or pose hazards. Avoid areas prone to high winds.

- Level the Base: Use adjustable brackets or stabilizers to ensure the base is level, enhancing stability and preventing tipping.

3. Assembling the Tower

- Unpack and Inspect Components: Lay out all parts on a clean surface and check for damage. Cross-reference with the user manual to ensure all components are present.

- Attach the Base and Mast: Securely connect the mast to the base using appropriate fasteners. Ensure all bolts and screws are correctly tightened.

- Mount the Lighting Fixtures: Attach the lighting fixtures to the top of the mast, aligning them per the manufacturer’s instructions for optimal light distribution.

4. Raising and Securing the Mast

- Extend the Mast: Raise the mast to the desired height using the designated mechanism (manual or electric winch). Ensure the mast extends vertically without leaning.

- Secure the Mast: Once extended, lock the mast in place using the provided locking mechanisms. If applicable, attach guy wires or deploy stabilizers to enhance stability, especially in windy conditions.

5. Connecting to Power

- Identify Power Requirements: Refer to the user manual to determine the lighting tower’s specific voltage and wattage requirements.

- Connect to Power Source:

- Generator Integration: If using an integrated generator, ensure it matches the tower’s power requirements. Secure all connections to prevent power fluctuations.

- External Power Outlets: When connecting to external power sources, verify the outlet’s capacity and use appropriate cables and connectors.

- Safety Precautions: Always wear protective gear, such as insulated gloves and safety boots, during electrical setups. Ensure all power sources are deactivated before connecting and double-check grounding to avoid electrical hazards.

6. Testing and Operation

- Start the Engine: Follow the manufacturer’s instructions to start the engine. Allow it to run for a few minutes to reach operating temperature.

- Activate the Lights: Turn on the main breakers to illuminate the area. Adjust the lamp heads to direct light where needed.

- Monitor Performance: Observe the lighting tower for any abnormal noises or vibrations. Check the engine temperature and oil pressure to ensure proper operation.

The Bottom Line

Lighting towers are powerful and useful machines that bring light to dark places. Whether you’re managing a construction site, organizing an event, or handling an emergency, a lighting tower can help keep things safe and visible.

By understanding the types, uses, benefits, and maintenance of lighting towers, you can choose the best one for your needs and use it efficiently.

Whether powered by diesel, battery, or the sun, lighting towers are essential in modern life—they brighten the way, no matter the time of day.